Responsibly Dyed Since 2012. Our Partnership with bluesign®.

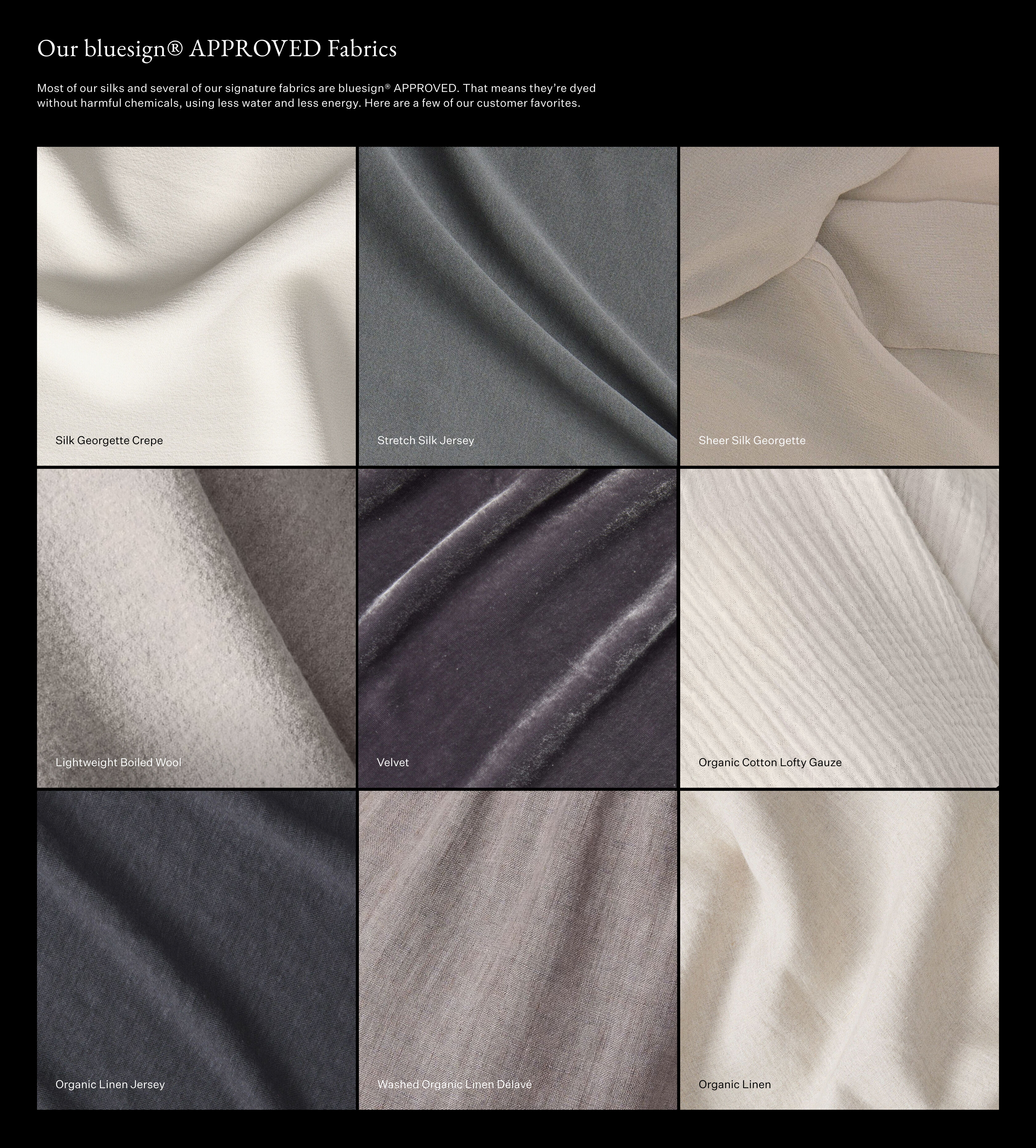

In 2012, we introduced responsibly dyed silk—a first for the fashion industry. Today we’re continuing to partner with bluesign® to improve the way our fabrics are finished.

As the first fashion company to partner with bluesign®, we helped the dyehouse behind our signature silks transition to using safer chemistry. It wasn’t easy, but it was worth it. Since 2012, we’ve done the same for many of our signature fabrics, because we believe in sourcing materials responsibly. We want people to feel good about wearing our clothes—not just because they’re beautiful, but because they’re made in a way that puts people and the planet first.

Textile manufacturing is a complicated business. Before a fabric is dyed or finished, the materials may require processing at a fiber or yarn level—steps that don’t always happen in the same facility. Most garments are only tested for safety once they’re complete, making it difficult to correct any missteps in time for delivery to stores.

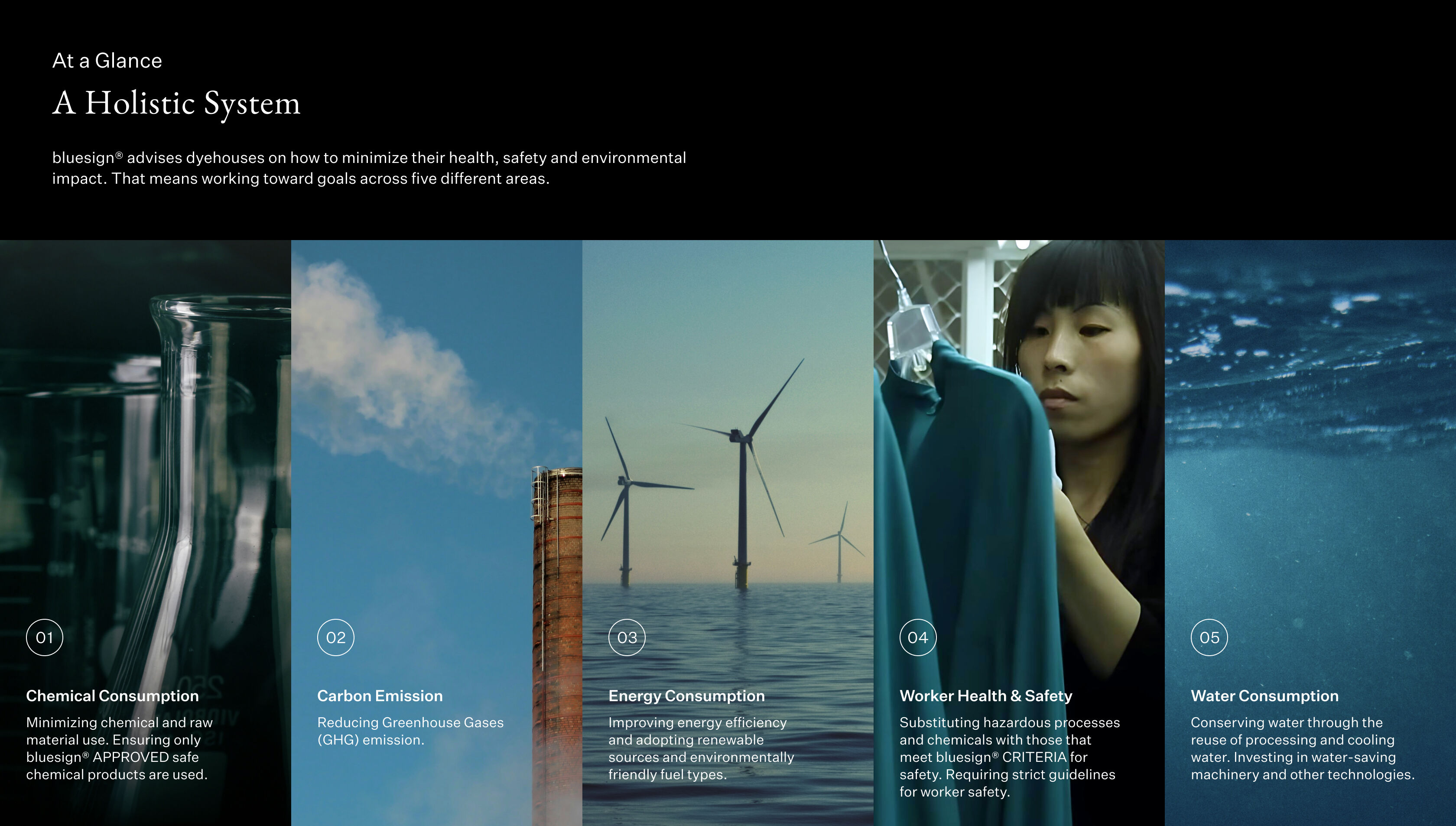

bluesign® takes a more proactive approach. By auditing chemical manufacturers and screening dyehouse inputs, the bluesign® SYSTEM helps prevent hazardous chemicals from ever entering the supply chain. That means keeping harmful dyes away from the people who wear our clothes—and the people who make them.

In addition to making sure our clothes are dyed responsibly, bluesign® requires dyehouses to use fewer resources and less energy—minimizing their overall environmental impact. It’s just one more reason we’re proud to have them as a partner.