3 Solutions for Textile Waste: What We're Doing with Your Damaged Clothes

We’re working to keep worn-and-torn EILEEN FISHER clothes in the cycle of use as long as possible. Why? They’re simply too good to waste.

Touring the Renew warehouse in Irvington, New York, with Carmen Gama, Director of Circular Design, the first thing you'll notice is the sheer quantity of clothes. Boxes of pre-loved EILEEN FISHER pieces on the floor, piles of garments on tables waiting to be sorted and hundreds of bags of clothes in storage—all full of possibility. “We get about 30 large boxes filled with clothing shipped to the warehouse each day,” Carmen explains. “Our teams are really efficient at sorting through the clothes, separating them by fabric and color and figuring out where they need to go.” Pieces that are in great condition are cleaned and resold through our Renew program. But what do we do with the 100,000+ units of damaged clothes sitting in our warehouse? That’s the daunting question that Carmen is working to solve.

“There’s no one solution for textile waste,” Carmen says. Keeping our clothes in the cycle of use requires a multipronged approach, ongoing research and, above all, determination. Learn more about how Carmen and the EILEEN FISHER team are designing solutions for damaged EILEEN FISHER clothes.

Solution 1

Special Collections

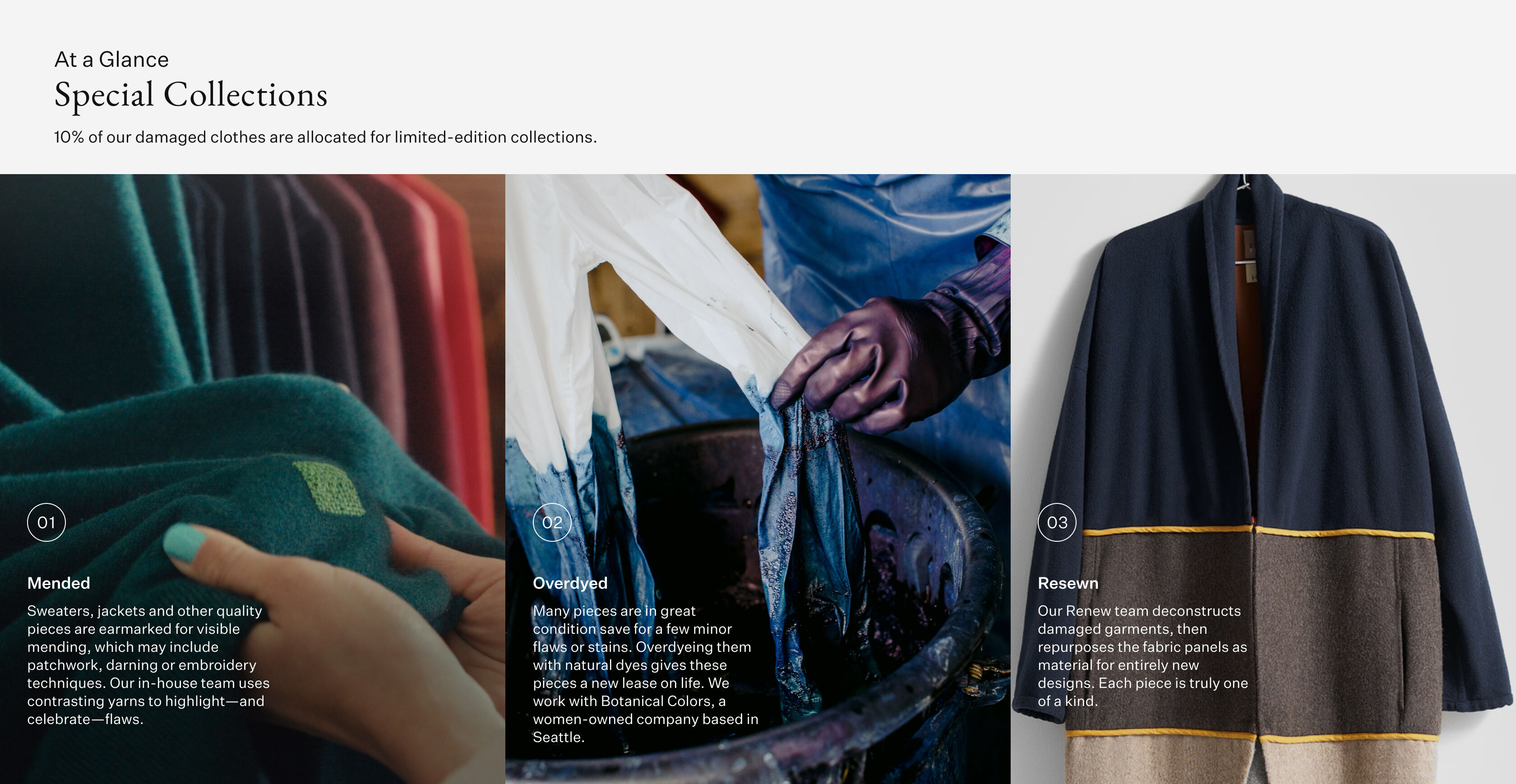

Some of the clothes we take back have slight damage or flaws. As part of our commitment to circular design, we’re working to give these pieces many more years of wear. We clean every garment using an environmentally friendly process, then breathe new life into them using one of three techniques: mending, overdyeing or resewing. You can find limited-edition special collections available for purchase at eileenfisherrenew.com.

“Right now, we are working to shift our internal operations and create more efficient processes so that we can offer more special collections in the future,” explains Carmen. Although these initiatives are essential to building a truly circular system, they are logistically difficult to scale, which is why they are part of a multifaceted approach to tackling textile waste. Repairing or repurposing each garment is a labor of love that requires skilled hands and a creative eye. The number of pieces our team can lovingly mend, overdye or resew is limited; however, by offering these collections, we hope to inspire others to see the beauty and possibility in old clothes.

“Our clothes are made with natural fibers and quality materials that inherently allow them to live multiple lives.”

–Carmen Gama, Director of Circular Design

The circular sweater, made with 80% recycled wool spun from pre-loved EILEEN FISHER garments.

Solution 2

Fiber-to-Fiber Recycling

Roughly 57% of our damaged inventory is set aside for textile recycling, which means the garments are sorted by color, then mechanically shredded and respun into new yarns from which new fabrics can be made. Currently, we send our linen garments to Hallotex in Spain and our wool to Re-Verso in Italy. “We’ve been working with this Italian mill for a long time,” explains Carmen. “It's only because we have a longstanding partnership that they’ve agreed to take our wool back. Building strong relationships has allowed us to do this work.”

Carmen has made it her mission to increase the percentage of damaged EILEEN FISHER clothes that are recycled, but the challenges that we as a brand and an industry continue to face are complex and numerous. For one, the majority of mechanical recyclers require feedstock that comes from a single fiber. Many mills will take back garments made from 100% cotton or wool, but there’s less demand for silk—let alone blended materials or fabrics made with polyester, elastane or spandex. “It breaks my heart that some of our most gorgeous materials like Hemp or Organic Linen Cotton aren’t currently recycled,” says Carmen. “The sad truth about many of these fabrics is that even though they start their first life as sustainable fibers, it's hard right now for us to find partners who are willing to convert them to new fibers at the end of their life.”

Additional industry-wide hurdles include lack of infrastructure and high costs. Currently, textile recycling companies can earn more per pound selling clothes to exporters for resale in secondhand markets, where they often disrupt local economies and contribute to environmental pollution. “The majority of clothing isn’t ending up in the fiber-to-fiber recycling space to begin with,” says Carmen.

Although we are actively working to increase the number of EILEEN FISHER garments that are recycled into new yarns, it’s important to note that this is just one step toward closing the loop. Only the smallest fraction of the clothes that we send for recycling are turned into yarn for new materials that end up back on our line. Our fabric team continues to research and develop recycled yarns that are every bit as luxurious as the virgin materials we’re known for. In our Fall 24 Collection, we were proud to offer a sweater with a truly circular backstory. It’s made with 80% recycled wool that was collected through our take-back program—a milestone for us.

For more information about the possibilities and challenges of fiber-to-fiber recycling, read “HEY FASHION!” (a report on the textile waste crisis funded by the Eileen Fisher Foundation).

“By doing this work ourselves, we want to prove to the industry that fiber-to-fiber recycling has the potential to truly scale. We’re streamlining our operations and creating a blueprint for others to follow.”

–Carmen Gama, Director of Circular Design

Solution 3

Downcycling

Roughly 33% of all the clothing we take back is designated for downcycling, which means that the fabric is mechanically shredded and turned into a product of lesser value often used as insulation for construction, rags or mattress stuffing (fun fact: this insulation is known as shoddy in the industry). Since 2019, we’ve partnered with Cyntex, a local company that processes our materials and ensures the shoddy is only sold to US manufacturers, thereby reducing carbon emissions from transportation.

Downcycling helps keep textiles out of landfills but is always a last resort because the materials degrade in value.

Toward a Circular Future

We’re proud of the progress our Renew team has made, but we're continuing to look ahead. It’s our hope that additional funding, infrastructure and new technologies will create opportunities for scaling circular solutions. “We’re always looking to partner with like-minded companies,” says Carmen. “We have an open door for brands and people to visit our recycling center because we don’t want this information to be proprietary. We all need to be working toward a solution.”

We'd Like Our Clothes Back Now

Bring your EILEEN FISHER clothes back to any US EILEEN FISHER or Renew store and receive $5 in Renew Rewards for each piece you return—no matter what condition it's in.

Don’t live near a store? Ship your items directly to our warehouse:

50 S. Buckhout St.

Irvington, NY 10533